The PTC Robot Challenge

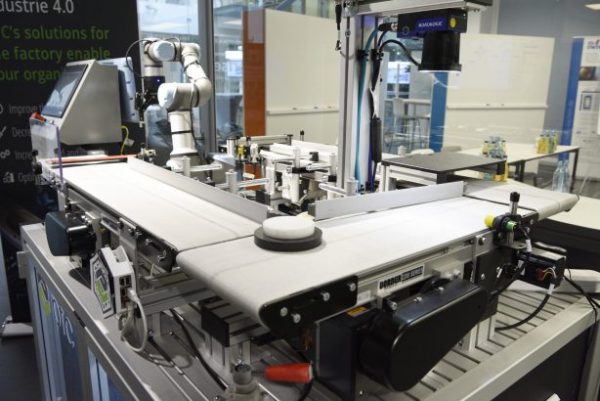

PTC’s software solutions support the manufacturing industry in developing, manufacturing, operating and servicing products. In this way, new competitive advantages are achieved in an increasingly intelligent, networked world. In order to test the software solutions mentioned above, PTC has built demonstrators that highlight problems in the manufacturing industry and can be worked through step-by-step and easily using an augmented reality application. One of two PTC robot demonstrators is located at the FIR at the RWTH Aachen University, which will demonstrate the following:

- The demonstrator should show that it has the ability to generate interference. (disturbances: vibrations, speed, leakage in the pneumatics)

- These faults are displayed in real-time on the iPad in the Control Panel.

- The app installed on the iPad allows you to take on different employee roles, which show different points of view and problem cases.